There has been a revolution in the logistic business of late, thanks to automation.

Huge corporations, notably Amazon, but also large national retailers with big expenditures in infrastructure and technology tremendous throughputs, and ambitious delivery schedules, have pushed for it.

That isn’t to say that these technical advancements are only financially viable for businesses with high throughputs, numerous locations, and six-figure capital expenditures. There are particular processes and technological adjustments that enterprises of any size may make to boost throughput and yield a high return on investment. There are immediate investments in automation that may be made to assure scalability and avoid bottlenecks as volumes expand.

Here are three of the best and cost-effective ways to automate logistics.

The transition from portable scanning to presentation reading

Handheld scanners made it feasible to employ barcodes to identify and track cartons and products. They are affordable, simple to use, and adaptable to a broad range of applications. They employ human brains and bodies to point to the code, thus they may be utilised for shelf reading.

They are, nevertheless, a good illustration of a scaling challenge.

But, on the other hand, handheld scanning is a laborious and a time-consuming operation.

To read a barcode on a box, we use a handheld barcode scanner in three steps:

- Pick up the product with one hand,

- Hold the handheld scanner in the other, and

- Scan the code by holding the scanner up to the code and activating it. It operates at the speed of a single operator.

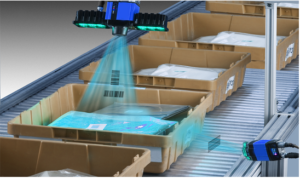

Scanning may be greatly expedited by switching to presentation reading, which is constantly on and in a fixed spot. The operator may swiftly process things or packages by passing an item beneath the barcode reader with one or two hands.

Presentation readers decrease worker fatigue and accidents by eliminating a variety of repetitive activities, including turning and picking up things of varied weights one-handed, which will increase as volumes increase in the absence of greater automation. Converting from a portable scanner to presentation reading may boost productivity by 25% and reduce cost per item chosen by 15%, with a ROI of only a few months.

Shifting from laser to image-based barcode reading.

A laser scanner consists of three major components:

- A light source,

- A sensor that detects differences in the light reflected off the barcode, and

- A decoder that turns those differences into data that is subsequently recorded, monitored, and stored in databases.

While they are affordable and well-known, laser scanners have a significant drawback which is their read rate. They have difficulty reading barcode labels that are broken, wrinkled, smeared, or badly written.

Image-based scanners provide much greater read rates and a slew of additional benefits.

In addition to scanning barcodes that laser scanners cannot read, image-based barcode readers can help with process optimization in ways that laser scanners cannot. Each barcode capture is an image in an image-based reader. In the event of a no-read, the photos can be used for root-cause study as well as real-time monitoring.

This can indicate that the root of the problem is a printer, a labeller, or that boxes are being placed on the conveyor in the improper orientation, allowing for simple changes to restore rates. This image-based data also aids in the maintenance of vendor compliance on inbound freight.

Image-based barcode scanners, when used in an overhead, stationary location, may greatly boost throughput by decreasing illegible or misread barcodes at high line speeds, while simultaneously giving the data required to improve operations.

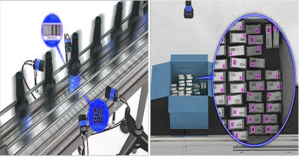

Transforming a single overhead scanner into a multi-sided tunnel

It might be challenging to maintain barcode quality, size, and placement, as well as package size and configuration, when a distribution centre receives items from a range of different vendors. Workers must reposition the packages so that they are properly aligned for reading. All of this manual labour wastes time and money, and it is an ineffective method to expand operations as volume increases.

Dahua’s six-sided code reading DWS system adopts “5+1” configuration, the bottom side uses 4K or 8K line scan camera, and the other sidesuses 20 MP high resolution smart camera for barcode reading. Dahua’s six-sided barcode reading system has faster, more accurate and moreeconomical processing capabilities and the system can help logistics companies have more advantages in the competition.